Maintaining consistent pressure across hydraulic circuits is essential for smooth system operation. The Magnetic Filter and Hydraulic Balancing Pressure Divider are two components that play a significant role in preventing operational disruptions. While the Magnetic Filter removes debris that can obstruct flow, the Hydraulic Balancing Pressure Divider ensures that each branch of the hydraulic system receives the appropriate pressure, helping to maintain stable performance and reducing stress on connected equipment.

Understanding Pressure Imbalance in Hydraulic Systems

Pressure imbalance occurs when certain branches of a hydraulic system receive more or less pressure than required. This can result in uneven performance, reduced efficiency, and increased wear on pumps, valves, and actuators. Over time, untreated imbalances can cause premature component failure or irregular system behavior. The Hydraulic Balancing Pressure Divider addresses this issue by evenly distributing pressure across multiple circuits, maintaining a more uniform operation throughout the system.

The Role of the Magnetic Filter in Supporting System Stability

Debris such as iron filings and rust particles can accumulate in water and hydraulic circuits, affecting pressure regulation. A Magnetic Filter captures these particles before they circulate, reducing the likelihood of blockages that can contribute to pressure fluctuations. Regular cleaning and inspection of the filter help maintain steady flow rates, which supports the Pressure Divider in its task of balancing pressures across the system. By managing both debris and pressure, these components work together to create a more predictable and stable operational environment.

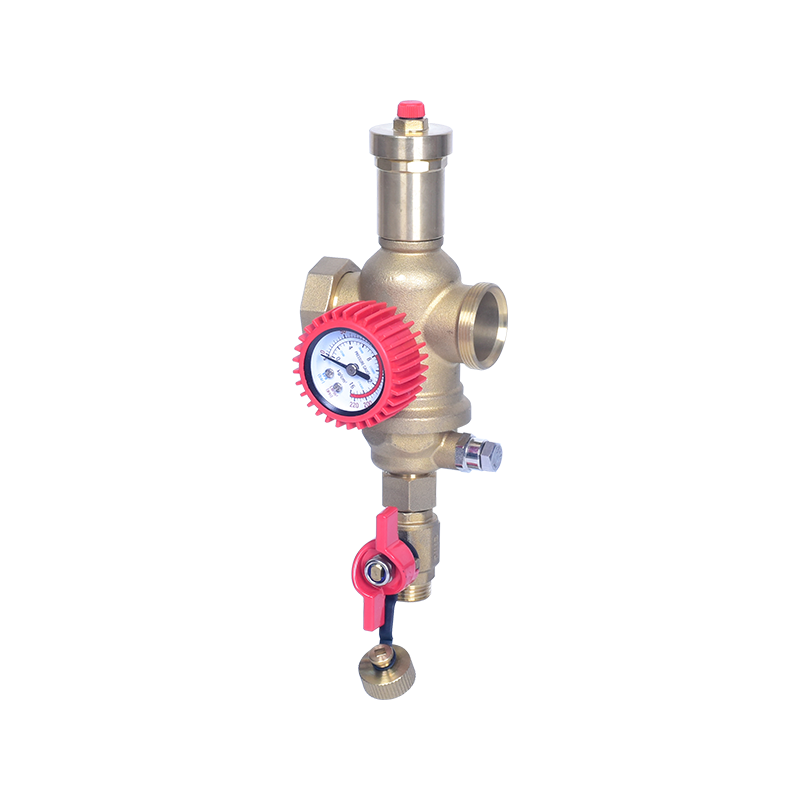

Design Features of the Hydraulic Balancing Pressure Divider

Constructed from durable 304 stainless steel, the Pressure Divider undergoes mechanical bending, extrusion, punching, welding, and polishing to ensure accurate and long-lasting performance. Its design allows fluid to be evenly routed to each branch, avoiding localized pressure spikes or drops. Even distribution reduces the stress placed on system components, preventing excessive wear and the risk of leaks. For operators, this means fewer maintenance interruptions and more consistent output from pumps and actuators.

Monitoring and Maintenance Practices

To ensure the Pressure Divider continues to prevent imbalances effectively, regular monitoring is recommended. This includes checking for leaks, inspecting connections, and verifying that pressures in each branch are within expected ranges. Combining this with periodic Magnetic Filter cleaning reduces the chances of clogging or debris-related pressure variation. Keeping maintenance records, such as inspection dates and observations, helps identify patterns and supports timely interventions before issues escalate.

Practical Implications for System Operation

When the Magnetic Filter and Hydraulic Balancing Pressure Divider are functioning properly, operators can expect smoother system behavior and more consistent performance. Pressure stability reduces energy fluctuations and ensures that pumps and actuators operate within their intended ranges. Additionally, balanced hydraulic systems are less likely to experience uneven wear, contributing to longer service life and reduced downtime.

Adapting to Different System Requirements

These components are versatile enough to handle a range of hydraulic and water circulation systems. The Magnetic Filter adapts to varying water conditions, capturing debris in both hard and soft water, while the Pressure Divider accommodates multiple branch configurations and pressure levels. This flexibility allows operators to maintain balanced operation in residential, commercial, or industrial applications, ensuring predictable system behavior under different operating conditions.

By combining careful debris management with pressure balancing, operators can address the root causes of uneven hydraulic performance. Consistent monitoring and maintenance of the Magnetic Filter and Hydraulic Balancing Pressure Divider provide practical measures to prevent pressure imbalance issues, contributing to more stable, efficient, and durable system operation.

Language

Language

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province