When upgrading an existing heating system, incorporating an Underfloor Heating Intelligent Controller can significantly enhance temperature precision and comfort while improving energy efficiency. However, successful integration requires attention not only to the electronic control unit but also to installation details, such as the proper use of a Tube Bend Support. Both components work together to ensure stable performance, efficient heat transfer, and extended system lifespan. Understanding the integration process helps homeowners and technicians achieve seamless functionality without disrupting the existing setup.

Assessing Compatibility and System Requirements

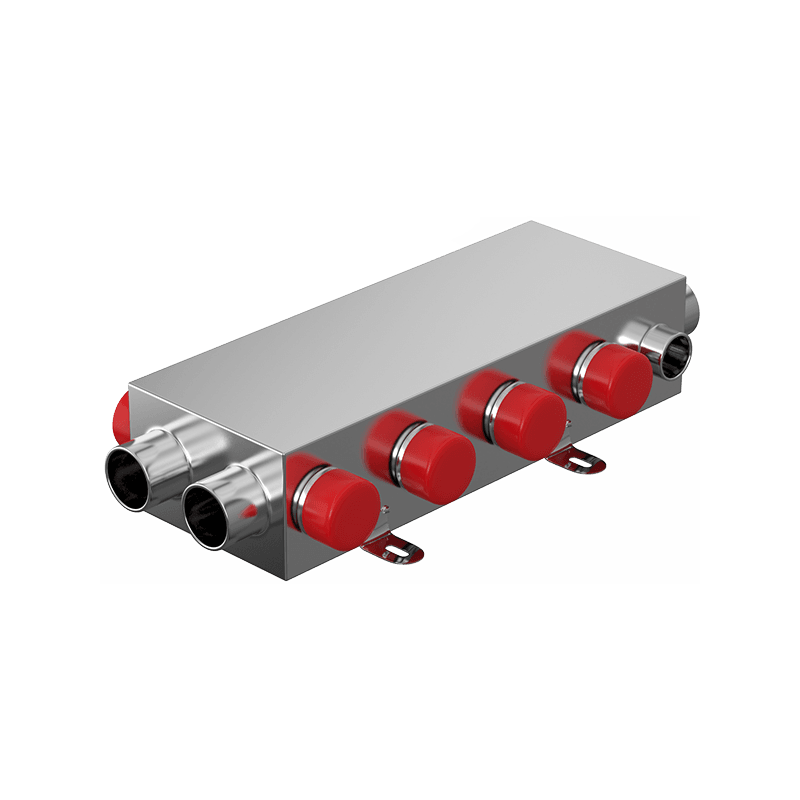

Before adding a new controller, it’s essential to assess the compatibility between the existing heating infrastructure and the intelligent control system. Factors such as the type of heating pipes, layout design, and the age of the existing thermostat can influence integration success. An Underfloor Heating Intelligent Controller typically connects to sensors, actuators, and the central manifold to regulate water temperature and flow. Ensuring that the electrical interface and communication protocols align with the existing setup prevents unnecessary modifications during installation.

For hydronic systems, verifying that the water flow rate and temperature range meet the controller’s specifications is crucial. The use of Tube Bend Support fittings during this stage helps maintain proper pipe routing, preventing bends or kinks that could affect circulation. Once compatibility is confirmed, users can proceed with a structured plan for wiring, calibration, and control settings.

Preparing the Installation Environment

Proper preparation creates a solid foundation for system integration. Before installing the controller, the electrical connections and floor heating circuits should be inspected for wear, corrosion, or irregularities. Any issues must be addressed to avoid interference with temperature readings or control functions.

At the same time, attention should be given to the mechanical integrity of the pipe layout. Tube Bend Support components are vital in keeping pipe turns stable and consistent. They reduce mechanical stress points that can arise from repeated temperature changes, ensuring that the water flow remains smooth through the entire heating circuit. Correct spacing and support positioning help the controller deliver accurate temperature regulation, since it relies on consistent thermal response from the floor.

Wiring and Connectivity Setup

Modern Underfloor Heating Intelligent Controllers often include modular wiring terminals or plug-in connectors for simplified installation. When integrating with an existing system, it is advisable to label all cables clearly and verify voltage compatibility before connection. Depending on the model, the controller may require linking with external temperature sensors, floor sensors, or Wi-Fi modules for remote monitoring.

For installations using smart home networks, pairing the controller with a centralized automation system can streamline energy management. Many intelligent controllers support app-based interfaces, allowing users to adjust temperature zones or schedules remotely. During wiring, mechanical stability must not be overlooked—Tube Bend Support aids in preventing cable or pipe displacement when electrical components are mounted or adjusted. This ensures long-term safety and consistency once the system is powered on.

Calibrating Sensors and Temperature Zones

After the wiring and mounting are completed, calibration is essential to achieve accurate readings. The floor and air temperature sensors should be positioned according to the manufacturer’s guidelines, ideally in locations that represent the average room condition. The controller then needs to be configured with appropriate temperature limits and time schedules that fit daily usage patterns.

For multi-zone systems, calibration ensures each area receives independent control, allowing different rooms to maintain separate comfort levels. In this process, stable pipe routing supported by Tube Bend Support plays a subtle but critical role. Uniform pipe curvature promotes consistent heat delivery, which helps sensors reflect true temperature changes rather than localized fluctuations caused by uneven heat flow.

Testing the Integrated System

Once the setup is complete, the next step involves a full operational test. The controller should be activated gradually, starting with lower temperature settings to observe response times and heating distribution. Monitoring system behavior during the initial hours of operation helps identify potential issues such as uneven heating, delayed response, or incorrect sensor data.

During testing, any irregular temperature variations may point to insufficient water circulation or misaligned tubing. Rechecking Tube Bend Support positioning can help address such issues, as improper support can cause partial flow restriction. Ensuring smooth circulation allows the intelligent controller to respond accurately to thermal feedback, achieving consistent comfort levels across all zones.

Language

Language

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province