In the plumbing and heating industry, durability and long-term performance are key considerations when designing components that support efficient system operation. A recent focus among manufacturers has been on improving the strength and functionality of hose bend support components used in various water systems. These supports are especially important in underfloor heating systems, where stable connections and consistent water flow are necessary for effective heat distribution. As underfloor heating installations become more widespread, the integration of systems like the Underfloor Heating Intelligent Controller has also become increasingly common.

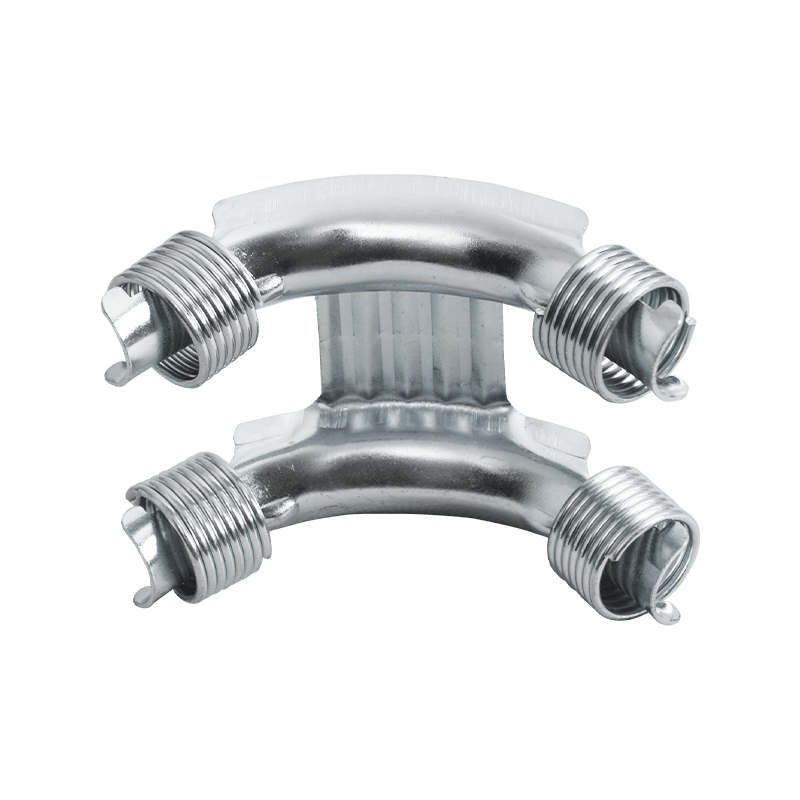

Hose bend support devices serve a critical purpose by maintaining the shape and positioning of flexible hoses, preventing kinks that could disrupt water flow. In traditional plumbing layouts, hoses may experience stress or movement over time. These supports offer a stabilizing structure that helps reduce strain on joints and fittings. New designs now emphasize materials that resist corrosion and wear, ensuring they can withstand continuous use in residential and commercial settings.

When installed in underfloor heating systems, hose bend supports work alongside control components such as the Underfloor Heating Intelligent Controller. This controller helps regulate temperature settings and operational timing, improving the heating experience and energy efficiency. However, without stable hose positioning, even the lots of accurate controls may fail to maintain consistent temperatures across a space. This interdependence underscores the importance of reliable hose bend support in modern system setups.

Many plumbing professionals have noted that failures in system pressure or water distribution often trace back to issues with hose placement. An improperly supported hose can shift, collapse slightly, or develop minor obstructions, pilot to inefficiencies. Using durable hose bend support components reduces these risks and supports the function of integrated technologies like the Underfloor Heating Intelligent Controller, which relies on precise inputs to function effectively.

Recent design updates have focused not only on the materials used but also on the shape and compatibility of hose supports with a range of flexible pipe types. Compatibility ensures quicker installation and fewer adjustments during maintenance. These seemingly minor changes can contribute significantly to the performance of systems that rely on coordination between mechanical parts and digital controls, including the Underfloor Heating Intelligent Controller.

Technicians installing new heating systems have found that the collaboration between physical support structures and digital regulation tools is becoming more streamlined. For example, the Underfloor Heating Intelligent Controller can now be programmed to respond to multiple zones within a building, but without reliable hose bend support, maintaining even heat distribution may still pose a challenge. Recognizing this, some installation guidelines now recommend pairing specific support models with advanced controller systems for balanced performance.

As homeowners and builders continue to prioritize systems that offer quiet, efficient heating, the importance of supporting infrastructure components should not be overlooked. The hose bend support may seem like a simple part of the overall design, but its contribution to system stability is vital. When paired with devices like the Underfloor Heating Intelligent Controller, it ensures that heating solutions function smoothly from installation onward.

Durability and compatibility in hose bend support designs are drawing more attention in the plumbing and heating sector. With more homes and commercial properties adopting the Underfloor Heating Intelligent Controller, the reliability of the surrounding components becomes even more important. This evolving relationship between mechanical supports and intelligent systems highlights the value of coordinated engineering across all levels of heating system design.

Language

Language

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province