OEM hydraulic underfloor heating balancing Manufacturing

Hydraulic underfloor heating has become an increasingly popular choice for homes and commercial buildings, offering an efficient and comfortable heating solution. The installation process of hydraulic underfloor heating systems, however, is not as simple as laying down pipes. It requires careful planning, precise execution, and an understanding of the building's structure. A successful hydraulic underfloor heating system depends on various factors, including the layout of the pipes, the choice of materials, and the installation of an effective insulation layer.

The initial step in the installation of a hydraulic underfloor heating system is the planning and design phase. This is where the layout of the system is carefully mapped out. Pipes are typically arranged in a serpentine or spiral pattern, designed to ensure that heat is evenly distributed throughout the floor. The spacing between the pipes plays an important role in the performance of the system. If the pipes are too close together, the system might overheat in certain areas, while too much space between them could result in uneven heating. Therefore, the hydraulic underfloor heating layout should be customized according to the size and shape of each room, ensuring efficient heat distribution.

Once the layout is determined, the next crucial step is the installation of the insulation layer. A well-designed insulation layer helps to prevent heat loss to the ground and directs the heat upward into the room. Without sufficient insulation, the system would be inefficient, and a significant portion of the heat would be wasted. Insulation materials such as foam boards or reflective mats are commonly used, as they help create a thermal barrier between the pipes and the floor structure. Installing this layer properly ensures that the hydraulic underfloor heating operates as efficiently as possible, keeping the heating within the room rather than dissipating into the ground below.

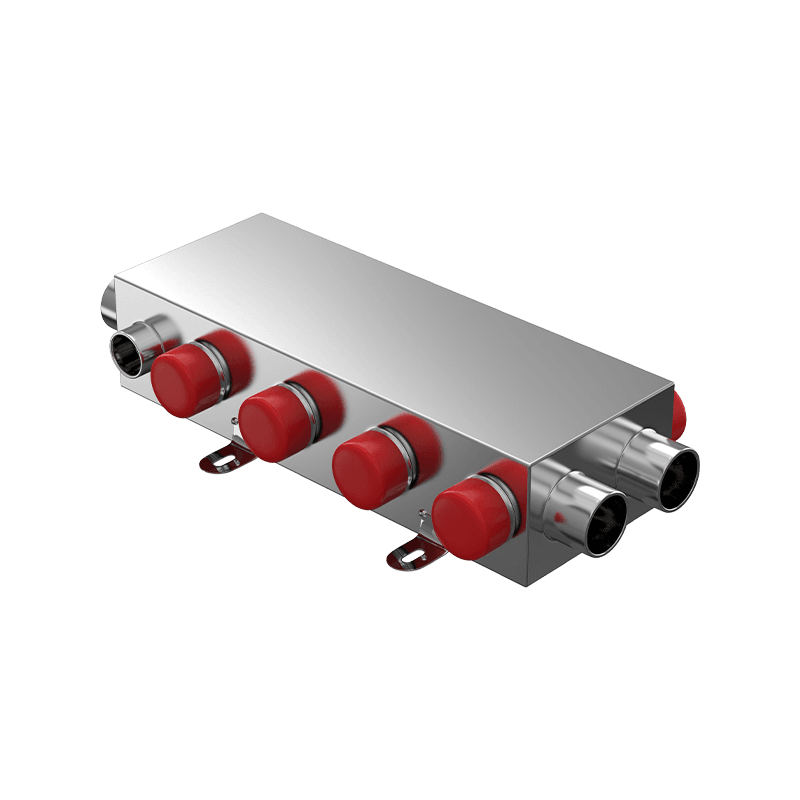

After the insulation is in place, the installation of the pipes begins. These pipes are typically made from cross-linked polyethylene (PEX), which is durable and flexible enough to bend around corners and adapt to the design of the room. The pipes are carefully secured to the insulation layer, ensuring that they do not shift during the next stages of the installation. Once the piping is complete, it is connected to the hydraulic manifold, a central component that controls the flow of water through the system. The manifold is typically placed in a convenient location, such as a utility room or closet, and acts as a hub from which the water is distributed to the various parts of the system.

When discussing hydraulic underfloor heating, it is essential to consider the type of flooring material that will be installed above the system. Different flooring materials can significantly affect the performance and efficiency of the heating system. For example, concrete is a popular choice for underfloor heating installations due to its good thermal conductivity. Concrete efficiently absorbs and distributes heat, making it an ideal material to pair with a hydraulic underfloor heating system. However, concrete floors require more time to heat up and cool down compared to other materials, so it is important to plan accordingly for long-lasting comfort.

On the other hand, wooden floors present a different set of challenges for hydraulic underfloor heating systems. While wood is a beautiful and highly sought-after flooring choice, it is not as conductive as concrete. As a result, the system may take longer to heat the room effectively. Additionally, wood tends to expand and contract with temperature changes, which could affect the integrity of the floor if not installed carefully. For this reason, it is crucial to install a hydraulic underfloor heating system under wooden floors with proper consideration for expansion gaps and the right temperature controls to avoid damage to the floorboards.

Another factor to consider is the depth of the floor construction. A hydraulic underfloor heating system requires a certain amount of space beneath the floor surface to allow for the pipes and insulation. In buildings with thin concrete slabs or where space is limited, installing the system might require additional adjustments or a raised floor solution to accommodate the necessary components. This can add complexity to the installation but is necessary to ensure that the system works effectively.

In conclusion, installing a hydraulic underfloor heating system involves a combination of careful planning, precise installation, and consideration of various factors that affect the system’s performance. From pipe layout and insulation to selecting the right flooring material, every step is critical in achieving a functional and efficient heating solution. While concrete floors tend to be the good option for hydraulic underfloor heating due to their thermal conductivity, wooden floors can still work well with proper installation and adjustments. Whether building a new home or upgrading an existing one, hydraulic underfloor heating provides an efficient and comfortable way to heat any space, provided it is installed with attention to detail.

Language

Language

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province