Modern underfloor heating systems are increasingly paired with digital management solutions, where an Underfloor Heating Intelligent Controller works in tandem with a Manifold Cabinet to regulate water flow and temperature distribution across multiple zones. While the controller manages the timing and intensity of heating, the design of the manifold cabinet itself plays a significant role in how efficiently the system operates. Understanding this relationship helps homeowners, installers, and facility managers make informed decisions about system layout and performance.

Flow Distribution and Balance

One of the core considerations in manifold cabinet design is how water is distributed to each heating loop. Uneven flow can result in some areas receiving more heat while others lag behind, causing unnecessary adjustments from the intelligent controller. Cabinets with clearly separated channels and precise valve placement allow for more consistent water distribution. This ensures that each loop receives the intended flow, reducing the need for frequent intervention and adjustments.

A balanced distribution also helps the intelligent controller maintain the temperature settings more consistently. When the water supply matches the design parameters, the controller can operate within expected ranges, allowing rooms to reach the target temperatures according to schedule without overworking pumps or valves.

Space and Accessibility for Installation

Manifold cabinets vary in size and configuration, and these differences can influence installation quality and subsequent operation. Cabinets that provide ample space for piping connections, actuators, and sensors make the installation process more straightforward. Proper installation reduces the risk of leaks, airlocks, or other disruptions that can interfere with heating performance.

From a user perspective, accessibility matters when adjustments or maintenance are needed. Cabinets with accessible valves and well-organized layout allow users or technicians to service the system. Clear labeling and logical arrangement of the loops support easier calibration and reduce the likelihood of operational errors.

Integration With Control Systems

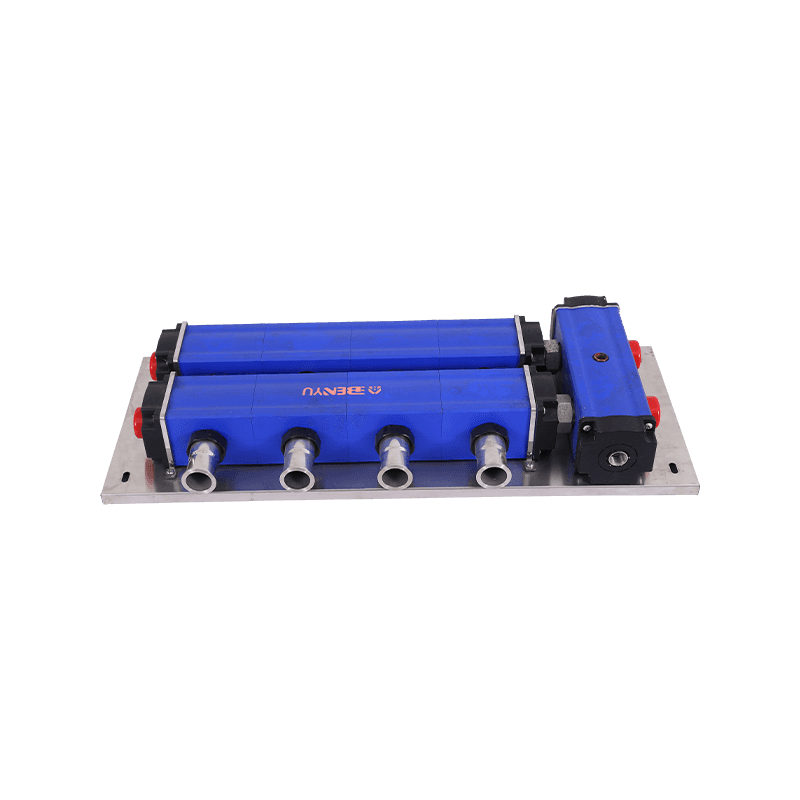

A well-designed manifold cabinet supports smooth integration with an underfloor heating intelligent controller. Actuators, sensors, and flow meters installed within the cabinet feed real-time information to the controller, allowing it to regulate pumps and boilers accurately.

Design features such as standardized actuator mounting, straightforward wiring channels, and clear identification of circuits help the controller receive accurate signals. When the cabinet design accommodates these components, the system can maintain temperature zones more evenly and respond appropriately to changes in heating demand.

Material and Thermal Properties

The materials used in a manifold cabinet also influence how heat is transferred and retained within the system. Cabinets constructed from materials with moderate thermal conductivity help stabilize water temperature as it moves through each loop. While the intelligent controller handles overall system timing and adjustments, the cabinet’s properties reduce sudden temperature fluctuations that could prompt unnecessary adjustments.

Durable materials also contribute to system longevity. Components that resist corrosion and wear maintain consistent flow over time. For users, this means fewer unexpected changes in performance and less frequent maintenance, allowing the controller to function according to intended settings.

Loop Configuration and Customization

Manifold cabinets offer flexibility in loop arrangement, which can affect heating distribution efficiency. Cabinets that allow for varied loop lengths or the addition of extra zones give installers and users the ability to tailor the system to the building’s layout.

A clear configuration helps the intelligent controller manage each zone effectively. By knowing the length and capacity of each loop, the controller can adjust pump activity and heating duration without guessing. This alignment between cabinet design and controller logic supports steady temperature regulation across rooms.

Air Management and Circulation

Air trapped within heating loops can affect flow and system response. Cabinets designed with accessible air vents or automatic air release valves help maintain smooth circulation. When air is removed efficiently, the controller can maintain set temperatures without encountering resistance in the pipes, reducing the frequency of corrective adjustments.

Proper air management also extends the lifespan of pumps and valves, ensuring consistent operation. For users, this means fewer disruptions and a system that responds predictably to changes in temperature settings.

Simplified Maintenance and Upgrades

A manifold cabinet designed for easy maintenance allows users or technicians to service the system without shutting down the entire heating network. Removable panels, modular components, and clearly labeled circuits simplify tasks such as valve replacement, sensor calibration, or adding additional zones.

This ease of access benefits the intelligent controller indirectly. When maintenance is straightforward, the system can return to normal operation quickly, reducing periods of uneven heating or fluctuating temperatures.

Language

Language

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province

Qigang Road, Huanghuaguitou Industrial Zone, Liu Shi Town, Yueqing City, Wenzhou City, Zhejiang Province